PRODUCTS AVAILABLE

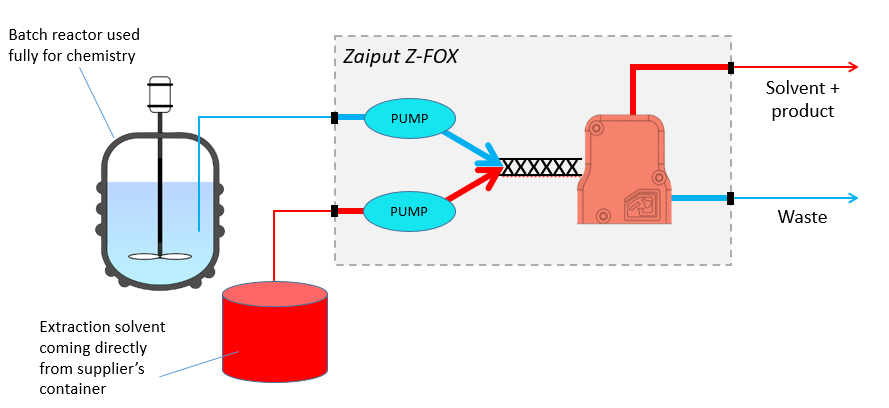

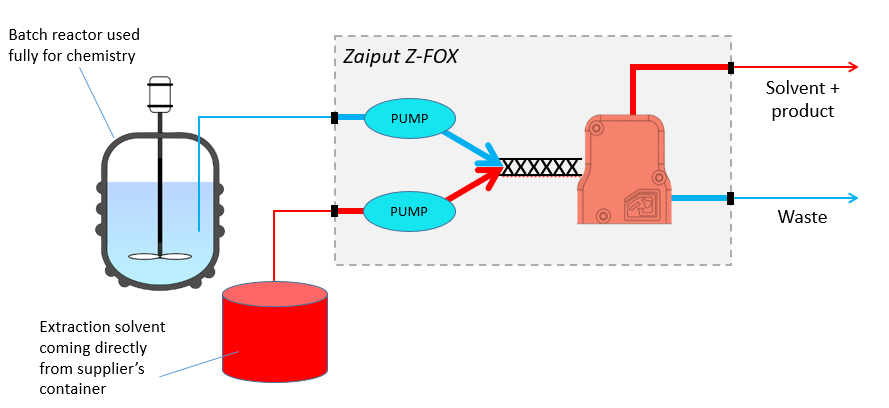

Zaiput separation technology is available at Production Scale, both as single separators for continuous or batch processes (SEP-3000, SEP-40K) and as integrated platforms for batch processes (ZFOX-3000, ZFOX-40K).

SEP-3000 and SEP-40K are the pilot and production scale versions of Zaiput’s membrane-based separators, available as plug-and-play passive separators. Zaiput Integrated Batch extraction platform (ZFOX) is a platform that enables a hybrid (batch + continuous) approach to extraction. The platform integrates Zaiput’s phase separator with pumping, engineered mass transfer (mixing) and controls to provide a turnkey solution for plant operators. This platform addresses the major challenges of batch-based liquid-liquid extraction.CURRENT CHALLENGES OF BATCH BASED CHEMICAL PROCESSING

- In many industrial chemical manufacturing segments (Pharma, Fine/Specialty Chemicals, etc.) liquid-liquid extraction (LLE) represents a very common post reaction purification step. Extractions are often performed in the same vessel as the reaction, relying on time consuming mixing for mass transfer and even slower gravity driven phase separation.

- While LLE is a well-established approach, from a production standpoint, there are 3 major shortcomings:

LOSS OF PRODUCTIVITY

- LLE in batch requires a reactor to have enough space to add the liquid phase used for the extraction. Hence when a reaction is followed by an extraction, only half (or less) of the reactor volume is actually used for the reaction. This substantially reduces the productivity of a reactor, at least by a factor of 2.

LOSS OF TIME WHEN PERFORMING MULTIPLE EXTRACTIONS

- Some processes require more than one extraction (or “wash”). Besides the low productivity, the sequential nature of the multiple washes multiplies the time needed. In other words, 2 extractions need twice the time, 3 extractions need three times the time, etc. This results in a production bottle neck from a time perspective

LOSS OF TIME DUE TO POOR MIXING AND SLOW TO SETTLE LIQUID PHASES (EMULSIONS)

The current approach to LLE hinges on stirrers for mixing and on gravity as a driving force for separation of the liquid phases. Better mixing that gives smaller droplets and hence better mass transfer unfortunately results in a mixture that is harder to separate. Current approaches rely on striking a balance between better mass transfer and making systems easier to settle; this results in waste of time, material and leads to suboptimal process conditions that impact process time.

Zaiput’s Z-FOX extraction platform solves these issues and more by integrating continuous membrane separation with engineered mass transfer. Now, reactors can be used to full capacity as the extraction is taken out of the reactor, emulsions are easily and immediately separated, and multiple extractions can be carried out in the same amount of time as it takes to carry out one. Z-Fox is a small footprint, mobile platform that can easily be moved around the plant to service many reactors – a versatile extraction solution to dramatically increase the output of previously installed capacity. Engineers and operators can reimagine their workflows and plant productivity with this new technology opening up a world where there is no more waiting for emulsions to settle, productivity goals are easily hit, and new extraction projects are easily scaled and implemented.